The company has integrated operations from blanking, forging, heat treatment, machining, surface treatment, packaging, etc. The main products are carbon steel, stainless steel, alloy steel, aluminum alloy, nickel base alloy flanges and forgings. The company has a flange and forging production line with an annual output of 20000 tons and a ring production line with an annual output of 10000 tons. The company has independent national laboratories and various testing and inspection equipment, which can carry out various tests and identifications of the company and external enterprises.

We believe that quality is the life of the enterprise, is our self-esteem, so it has become our main value, and implemented in our management system, so that we can contribute to our customers and ourselves.

We attach great importance to energy saving and emission reduction work, adopt natural gas heating system, effectively recycle waste materials, reduce the negative impact of our life and product production on the environment.

We pay attention to employee health and constantly improve the working environment.We put the safety of "people" as the first protection and attention position, constantly strive to achieve zero harm to people and prevent accidents.

We control the quality strictly according the QMS from raw materila, producing schedule, test and inspection, to the final delivery. We make the best control , give the reports and find out the reasons and keep improving our quality control .

We pay our heart during the quality control and we neven surrender to reach the best quality.

After the raw materials arrive at the factory, the raw material inspector shall verify the validity and content of the original quality certificate of the supplier according to the national material standards, and then inspect the specification, size, surface quality and identification (mainly the material and heat number) of the raw materials.

In the blanking process, the operator shall conduct self inspection on the first piece and mark the order number, material and heat number on the product, and then submit it to the full-time inspector to inspect the specification, weight, surface quality and identification of the first piece (order number, color code, heat number, and Flow Card with Pieces), after inspection and timely handle problems found.

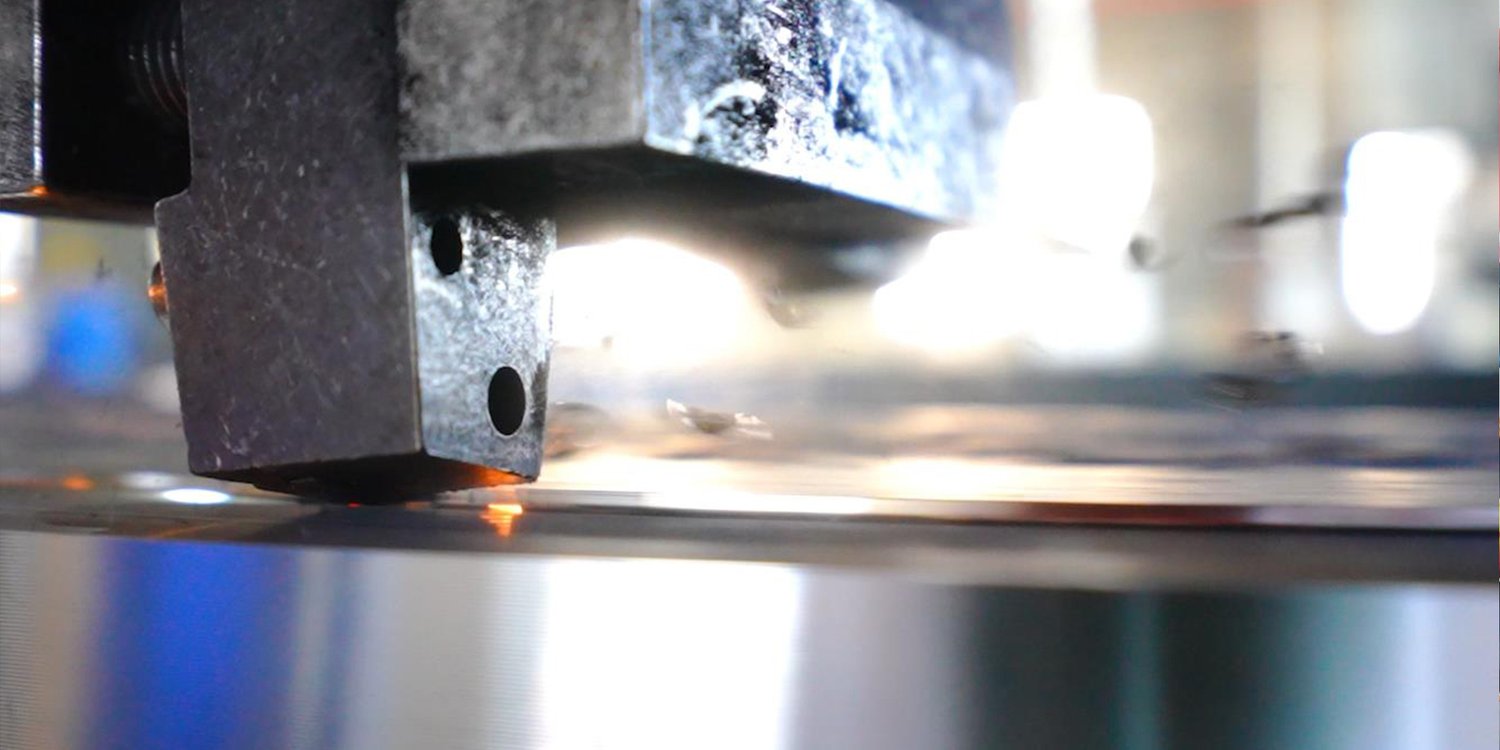

The inspector shall supervise and inspect the heating process parameters.

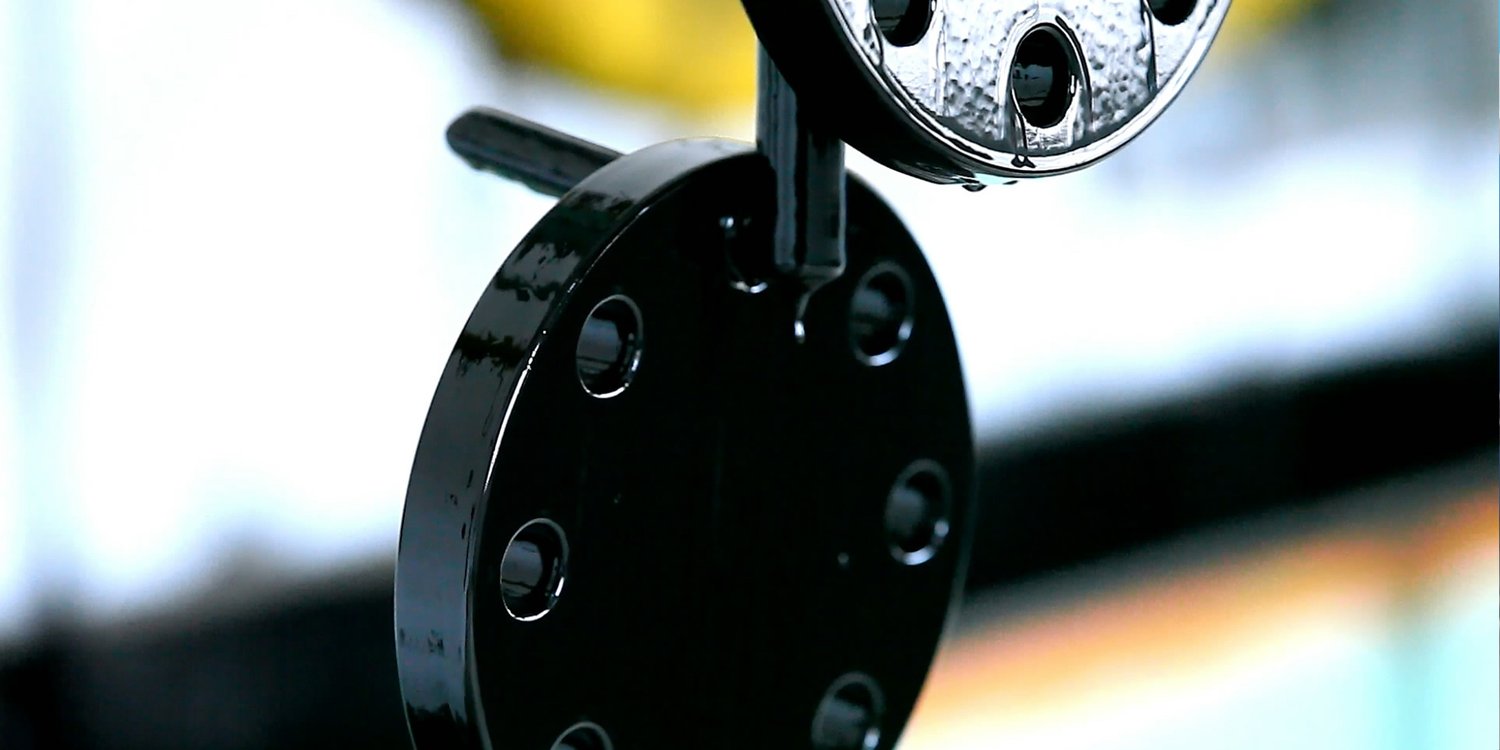

According to customer requirements, the physical and chemical laboratory will conduct UT inspection and issue inspection report. In the process of machining, random inspection shall be carried out on tour. After machining, inspectors shall inspect the aperture, hole distance, hole number, surface quality and mark according to the drawing paper, paying special attention to the aperture, position degree, burr and scratch of side hole.

Before packaging, the full-time inspector shall conduct 100% inspection on the size, surface quality and identification of the machined products in strict accordance with the drawings, and pay special attention to the surface roughness of the waterline part of the flange sealing surface, whether there are bumps and scratches, and whether the product identification is correct.

In the typing link, after the first article self inspection, the full-time packaging inspector shall conduct the first article inspection, and conduct batch typing after passing the inspection.

After the anti rust treatment is self inspected by the operator, the full-time packaging inspector shall carry out the first article inspection, patrol inspection and process inspection for the anti rust treatment and surface quality as required, and then enter the packing process if it is qualified, otherwise it shall be reworked

The packaging inspector shall inspect the packaging box in accordance with the Company's "Packaging Box Manufacturing Standard" and "Packing List". The inspector shall inspect the consistency of the product in the box with the shipping mark, product protection and other conditions, and can seal the box for packaging only after passing the identification.