Forging is the process of forming and shaping Metal using a Hammering, Pressing or Rolling method. There are four main types of processes used to produce Forgings. These are Seamless Rolled Ring, Open Die, Closed Die and Cold Pressed. The Flange Industry uses two Types. The Seamless Rolled Ring and Closed Die processes. All are started by cutting the appropriate sized billet of the required material grade, heating in an oven to the needed temperature, then working the material to the desired shape. After Forging the material is subjected to Heat Treatment specific to the Material Grade.

The Seamless Rolled Ring Forgings are made similar to other die Forgings. The Ring Forgings are formed by opposing rotating circular dies that simultaneously compresses the heated billet into a ring shape. Rolled Ring Forgings are available in excess of 200” in diameter.

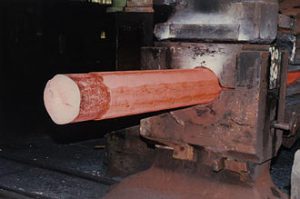

Open Die Forgings are produced by using two flat or shaped opposing Dies that are either Hydraulically compressed or Hammered to form the desired shape. The base material is open on the sides to allow for lateral movement, making for larger and heavier Forgings. These are typically Blocks, Bars or Cylinders.

The Closed Die Forgings are sometimes called Impression Die Forgings and are made using the same process as the Open Die Forgings. With this process the heated raw material is placed in a closed Die where no material is left exposed. The Die is then compressed either using the Hydraulic or Hammer method. This process requires much greater compression to ensure the cavities of the die are completely filled to form the part. Closed Die parts are smaller and produce near perfect shapes allowing for minimal machine work and high production runs.

Cold Pressed Forging is the most common of the Forging processes. Cold forgings are produced at room temperatures and require no preheating of raw material. Cold Forging produces parts that are free of scale and formed to tight tolerances so that machining is not required. Post production annealing is sometimes required depending on the material being formed and the application. Cold Formed parts are light weight and used in all types of manufacturing.